Why?

For a while now I've had a slightly different idea to build a magic car with a propeller which drives into the wind using the power of the wind.

|

| Advanced computer render |

No, it's not really magic, and no that's not a flower... it's a propeller.

The wind spins the propeller which spins some gears which spins some wheels. If the wheels produce more forward force than the wind produces reverse force the car will drive into the wind.

"Yeah, but why"?

Two why's is too deep.

Anyways, I ended up making something a little different than a wind car, but in the same vane.

I hope you acknowledge that pun.

I hope you acknowledge that pun.

Download

Video Overview

Thanks to John Willner for shooting half this video.

Design

From the very beginning I wasn't sure this whole project would even work. A really bad model and an even worse simulation was built in SolidWorks.

The only thing this crappy technology has in common with a Terminator is the floor tile.

... but it may actually work.

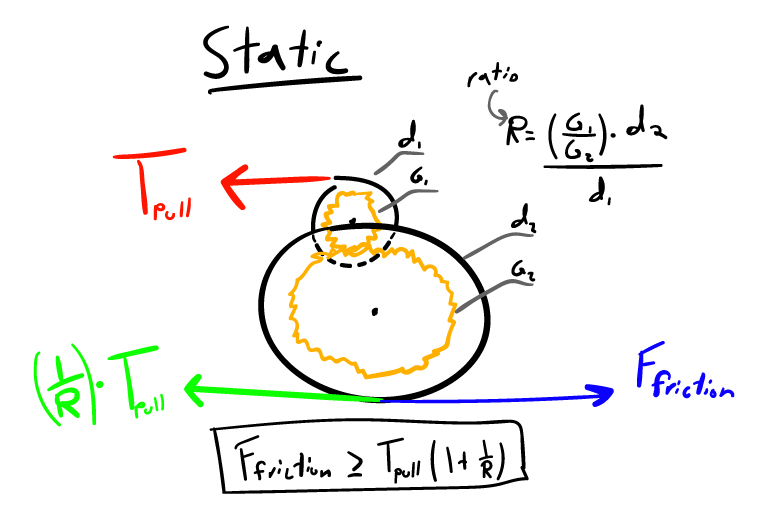

I wanted to keep the gear reduction as close to 1:1 as possible, squeezing the most forward movement out of each string pull. However, the only force not trying to pull the car backwards is our frenemy friction. The amount of friction between the wheels and ground needs to be relatively large.

Movement introduces an additional component: acceleration force. The force required to accelerate the car depends on how fast the string is pulled; this is in addition to the forces drawn above.

Here are the first iteration parameters for a gear reduction of 0.82:

|

| SolidWorks simulation |

... but it may actually work.

I wanted to keep the gear reduction as close to 1:1 as possible, squeezing the most forward movement out of each string pull. However, the only force not trying to pull the car backwards is our frenemy friction. The amount of friction between the wheels and ground needs to be relatively large.

|

| Static Solution |

Here are the first iteration parameters for a gear reduction of 0.82:

- Pulley diameter = 0.75in

- Wheel diameter = 1in

- Pulley Gear = 16 teeth

- Wheel Gear = 26 teeth

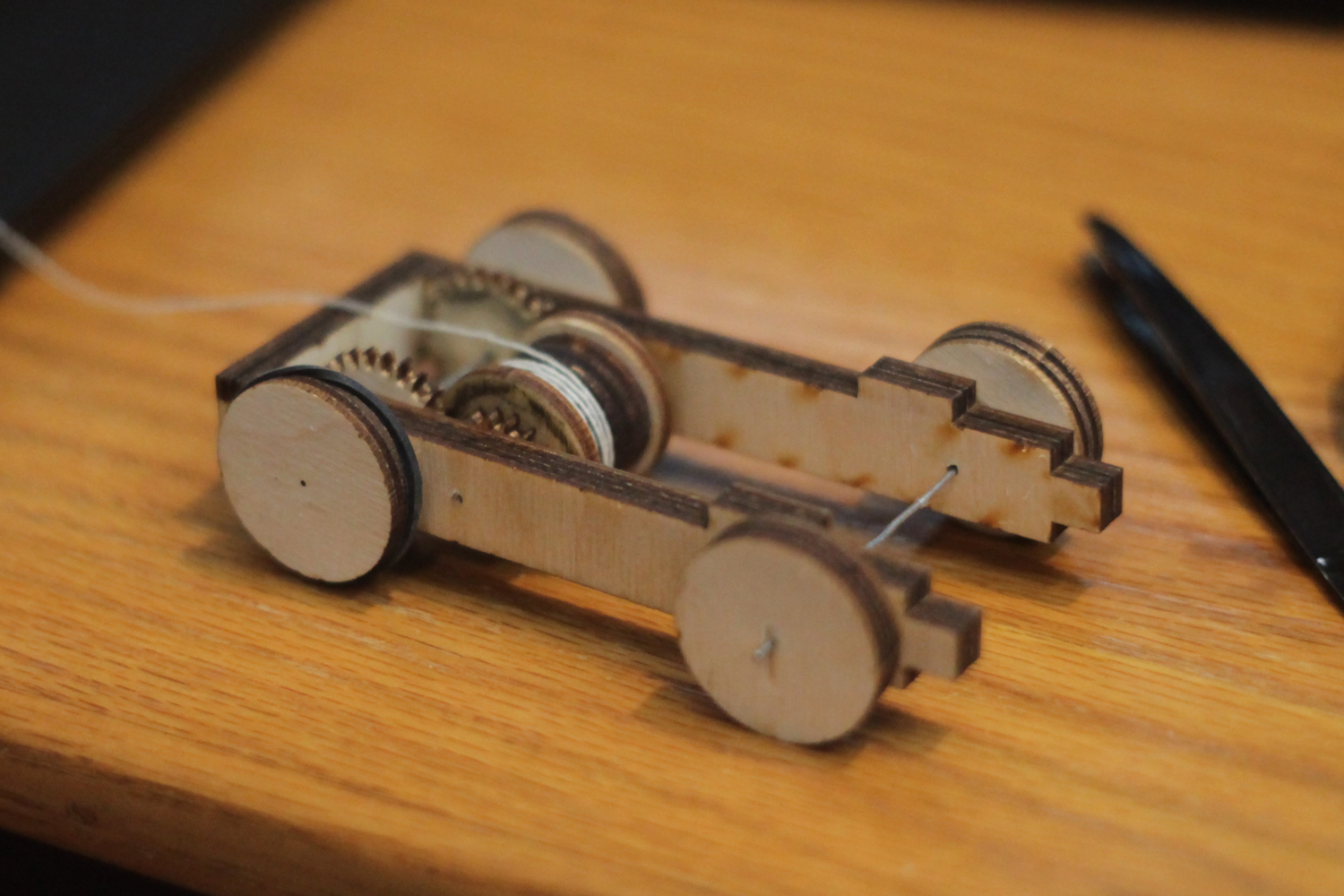

Ok, I lied. Those were actually from the second iteration. My first attempt I messed some numbers up and built a gear ratio greater than 1.0 which didn't work at all.

I put small rubber bands around the wheels to increase friction.

I put small rubber bands around the wheels to increase friction.

|

| "First" test |

Everything worked! But not as well as I had hoped... The car would get stuck and performed inconsistently due to friction in the drive train. Reducing the gear ratio should help.

I changed the first gear from 16 teeth to 14 teeth putting the ratio at 0.72, and loosened up the gear mesh.

| Loose gear mesh |

At this point I modified the model in attempt to hide the inner workings.

|

| Working toy car |

Conclusion

I overestimated people's reactions to pulling the string for first time.

The End

That's is it's.

See you next time.

Anyway to get an stl or even the solid works file for the pieces? Id love to 3d print my own

ReplyDeleteHey, what would happen if you tethered one and end and gave the car a bit of initial velocity, will it just drive away until the string runs out? My intuition of the physics is you have to actively be doing work on the string end or something but its just one of those confusing problems :P

ReplyDeleteThis comment has been removed by the author.

DeleteNewton's first law explains that an object at rest stays at rest and an object in motion stays in motion until acted upon by an outside force. The string acts as the outside force to begin motion, and friction is the outside force that causes it to end motion. Giving the car inertia by rolling it would just allow it to go until friction causes it to stop, not having enough energy to pull the string. (Unless you push the car so hard it doesn't matter about the string.) If you notice in the video that was posted, when someone laggs on string pulling, the car slows and almost stops even though it has some forward momentum.

Delete